Not known Incorrect Statements About Premier Aluminum Llc

Not known Incorrect Statements About Premier Aluminum Llc

Blog Article

A Biased View of Premier Aluminum Llc

Table of Contents6 Simple Techniques For Premier Aluminum LlcThe 9-Second Trick For Premier Aluminum LlcThings about Premier Aluminum LlcThe 25-Second Trick For Premier Aluminum Llc

(https://profile.hatena.ne.jp/premieraluminum/)Commonly, a buyer's primary responsibility was to locate certified and responsive distributors. Sometimes, purchasers thought that any provider going to contractually satisfy the purchase requirement was qualified. Nonetheless, making use of inexpensive and unqualified distributors can create quality problems, and lost time and cash in the lengthy run. To help you via the procedure, right here are some things to consider when selecting the ideal metal casting supplier.

For instance, a business that just uses the investment spreading process will certainly try to sell you on why that procedure is best for your application. Yet what happens if making use of the sand casting process is best for you and your requirements? Instead, seek a vendor that offers a variety of casting procedures so the most effective alternative for YOU is selected

If functioning with a single source for all of your casting needs is essential to you, the provider requires to be diverse in its abilities. When integrated with other integrated abilities, this can assist streamline and press the supply base. When picking the right spreading provider, mindful factor to consider needs to be offered to high quality, service, and price.

The Greatest Guide To Premier Aluminum Llc

Buyers significantly pick spreading vendors that have machining abilities. If the casting supplier uncovers a problem during machining, the issue is dealt with faster with no dispute over whose mistake it is.

Trouble or no, incorporated machining streamlines the supply chain and decreases dealing with time and delivery price before the item makes it to the consumer. What do you require from your casting provider? Are you seeking somebody to just provide a metal part to your doorstep or do you need extra? If you do not have internal metallurgy experience, confirm that the supplier can give advice in choosing the correct alloy based on your certain application.

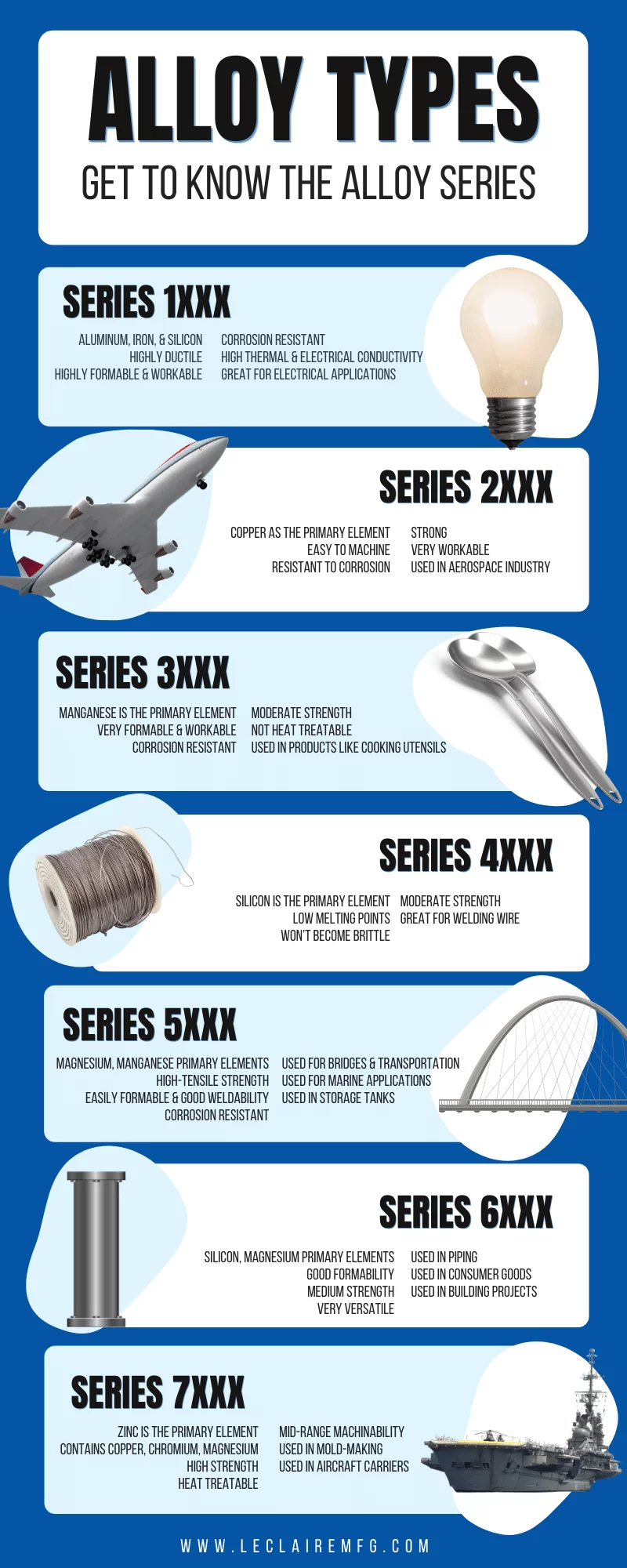

Some foundries are restricted or specialized. Make sure the provider can satisfy all your material or alloy demands to remove the need for numerous providers.

The Of Premier Aluminum Llc

Research the distributor's web site. Talk to a sales rep or company associate.

Aluminum is additionally light-weight and has excellent corrosion resistance, making it optimal for applications where weight and sturdiness are very important aspects. Furthermore, light weight aluminum casting is an economical technique of production, as it calls for much less energy and resources than other methods. Iron spreading, on the various other hand, involves putting liquified iron right into a mold and mildew to create a desired form.

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Iron spreading is additionally able to endure high temperatures, making it appropriate for usage in applications such as engine components and commercial machinery. Iron spreading can be extra costly than light weight aluminum casting due to look at this now the higher cost of raw materials and the power called for to thaw the iron. When deciding between light weight aluminum casting and iron casting, it is very important to think about the specific needs of the application.

In final thought, both aluminum spreading and iron spreading have their own one-of-a-kind benefits and downsides. There are three sub-processes that fall under the classification of die spreading: gravity die spreading (or permanent mold and mildew spreading), low-pressure die casting and high-pressure die casting. To obtain to the ended up product, there are three main alloys made use of as die casting product to choose from: zinc, light weight aluminum and magnesium. Report this page